PRODUCTS

ULPA Filter

Ezi-Duct & Polex Environmental Engineering, Australia’s leaders in Air Filtration Equipment, have combined their many decades of experience to design and manufacture an air filter to meet the demands of the COVID-19 health crisis currently affecting the world.

The ULPA Filter is a powerful yet portable air filtration apparatus that can filter and remove 99.99% of the particulates that are 0.12 μm or more in diameter. Constructed from hygienic stainless steel material, the ULPA Filter can be easily disinfected after use.

Even with the high airflow the ULPA Filter is only 750 mm wide and can be wheeled through a standard doorway and runs on single phase power. The ULPA Filter Hi-Efficiency Fan has a powerful yet variable air flow of up to 3500 m3/h @ 1000 Pa pressure.

ULPA Filter can either operate as a standalone unit in larger areas or ducting can be connected to it to filter the air from several smaller rooms. It can be used in such areas as hospital or medical centre waiting rooms, schools or university classrooms, office environments, shops, supermarkets, age care facilities,restaurants, clubs and anywhere where people gather.

What is the difference between HEPA and ULPA filters?The key difference between industrial HEPA filters and ULPA filters is in the size of the particles they can remove. While HEPA filters can remove up to 99.97% of contaminants as small as 0.3 μm in diameter, ULPA filters can remove 99.99% of the particulates that are 0.12 μm or more in diameter. |

The team at Ezi-Duct and Polex Environmental Engineering have combined their decades of industry experience in designing and manufacturing to meet the demands of the health crisis affecting the world.

What

The ULPA filter is a powerful yet portable filtration apparatus that can filter and remove 99.99% of the particulates that are 0.12 μm or more in diameter. It can conceivably lower the amount of particulates, including pathogens from the environment, both from the air and potentially from surfaces.

WhyThe ULPA Filter air recirculation unit has been developed in response to the international outbreak of COVID-19 virus. This unit has been specifically designed to be used inside enclosed spaces where multiple people are present. Contaminated air is efficiently extracted from within the room and is filtered through an array of ultra high efficiency filters before releasing filtered air back into the room.

HowThe filters use advanced filtration media (ULPA 16) specifically designed, sized and selected to filter particles as small as 0.12 μm. Filtering such small particle sized produces high resistance which is overcome with a powerful high efficiency backward curved extraction fan.

Specification

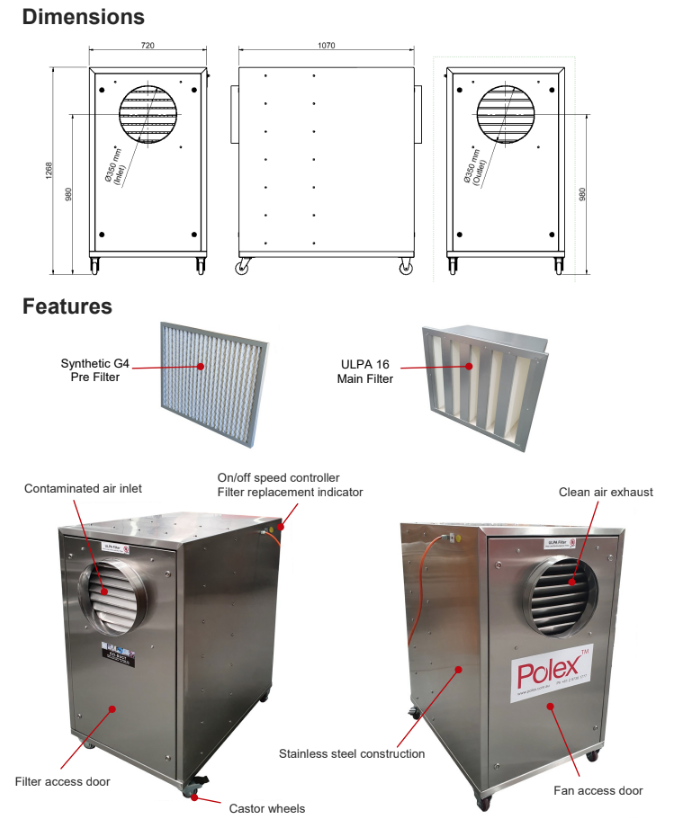

| Dimensions (W x L x H) | 700 x 1050 x 1300 mm | Main Filter | ULPA16 |

| Airflow | Up to 3,500 m3/h | Pre Filter | Synthetic G4 |

| Pressure | Up to 1,000 Pa | Speed control | Infinite |

| Power | 1.5 kW | Materials | Stainless steel 304 (#4) |

| Full Load Current | 10 A | Construction | Bolted |

| Speed | 2,850 rpm | Wheels | Lockable castors |

| Phase | Single | Electrical Connection | 3 pin plug (10 A) |

| Frequency | 50 Hz | Certification (electrical) | CE |

| Protection | IP55 | Certification (filtration) | ULPA 16 |

Benefits

Reduce risk of viruses being spread Continuously extract and filter air and reduce the risk of potentially contaminated air.

Assist HVAC systems Assist existing HVAC systems and to avoid recirculating air between rooms.

Minimise contaminated PPE One of the highest-risk activities is the removal of contaminated PPE for Health care workers treating infected patients.

Having an additional filter to purify surrounding air and not just the air being breathed may reduce the amount of contamination of PPE and other objects and surfaces in the vicinity.

Applications

| General hospitals | Temporary hospitals | Medical centres |

| Operating theatres | Patient treatment rooms | Chemists / Pharmacies |

| Schools and universities | Childcare centres | Retirement homes |

| Shopping malls | Service stations | Centrelink centres |

| Clubs and bars | Restaurants | Cafes |

| Banks | Post offices | Offices |

| Cinemas | Waiting rooms | Medicare centres |

Configurations

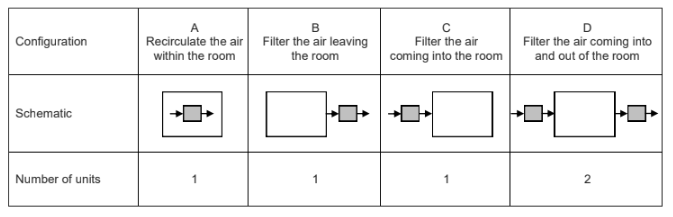

The unit can be used in many configurations.

- Recirculation unit: The ULPA filter can be used for patients with a known or suspected infection in hospital rooms with multiple beds, whether in a hospital room or in self-quarantine. The units can be kept near the patients at all times and left by their bedside while resting. This configuration can be used in many general areas such as school classrooms and restaurants.

- Negative pressure: The ULPA Filter can be used as a negative pressure isolation room for use with patients.

- Positive pressure clean air system: The ULPA Filter unit can be used as a positive pressure clean air recirculating system in clinics, waiting rooms, hospital emergency rooms and other confined areas for air being exhaled from patients.Positive and Negative: Introduce filtered air and exhaust contaminated

Number of units required (based on room size and configurations A, B and C)

The number of units required can be calculated by multiplying the width, length and height of the room in metres and referring to the table below.

| Room volume (m3) * | Up to 250 m3 | Up to 500 m3 | Up to 750 m3 | Up to 1000 m3 | Up to 1250 m3 |

| Number of units required | 1 | 2 | 3 | 4 | 5 |